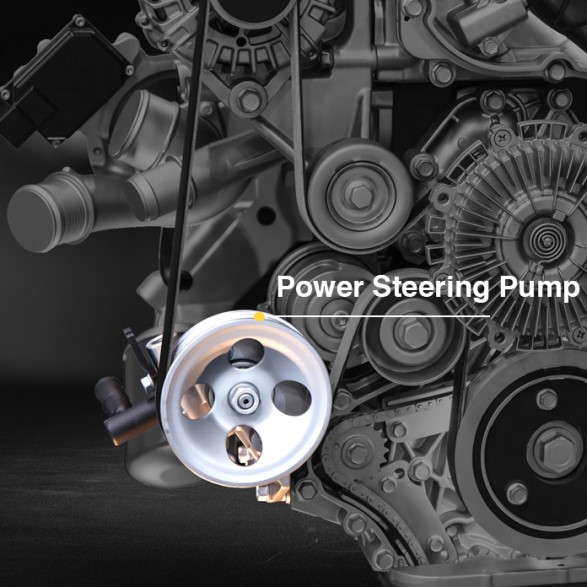

The power steering pump is the heart of your hydraulic power steering system. It is driven by the engine’s accessory / serpentine belt which in turn helps to aid the driver in steering the vehicle more lightly.

How the Power Steering Pump works

Having an insight into how the power steering pump works is crucial in understanding why a brand-new steering pump is a better choice rather than buying a remanufactured steering pump.

As the driver turns the steering wheel in any direction, the power steering pump applies pressure to the steering gear which turns the vehicle’s front wheels. Hydraulic fluid always runs throughout the system. The pressure that the fluid applies to the steering gear is controlled by a set of valves that are opened or closed depending on how much force is applied to the steering wheel, vehicle’s speed, and several other factors.

A deeper look into the power steering pump…

As hydraulic fluid enters into the steering pump, a shaft propelled by the pump’s pulley turns a rotor which applies centrifugal force to the fluid sending it to a series of pockets. As the fluid moves throughout the pockets it then builds pressure. Pressurized fluid leaves the power steering pump and goes to the high-pressure port. Some pumps have more than one rotor, so they may have two or more low-pressure and high-pressure ports. Passages and veins which assist in the pump in building pressure are located inside the pump’s case.

The rotor is mounted over a bearing to minimize friction with the pump’s case. Power steering pumps have a built-in flow control valve designed to control the pressure of the hydraulic fluid coming out of the pump. Without the valve, the fluid’s pressure from the pump would be too high at high engine RPMs.

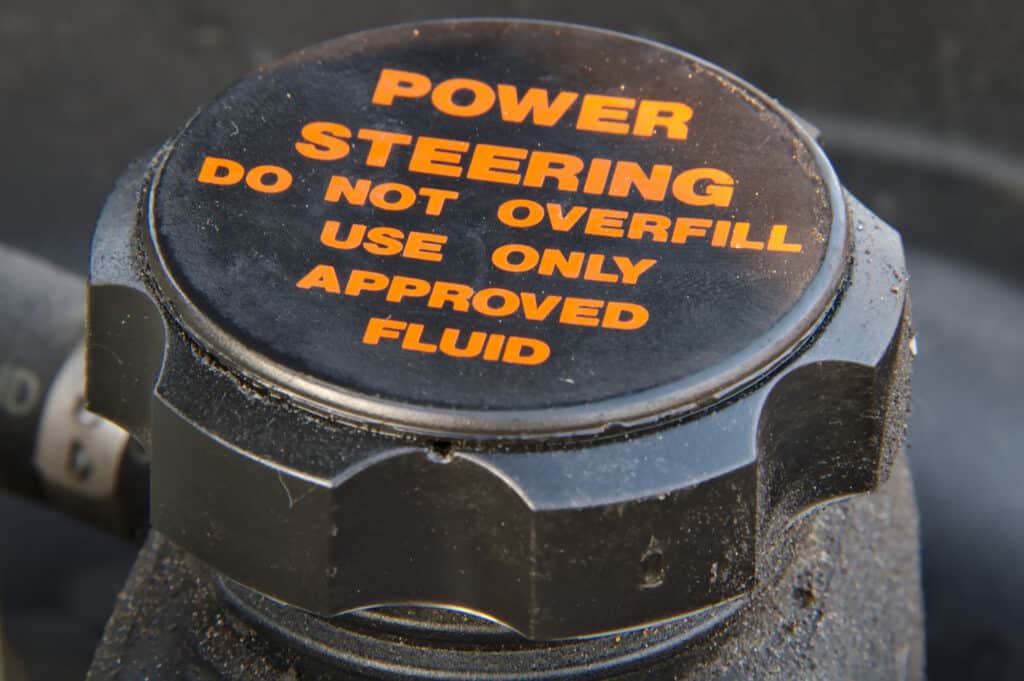

The power steering pump is lubricated by the hydraulic fluid as it compresses it. A lack of hydraulic fluid will ensure that there is metal-to-metal contact within the pump which guarantees that it will cause severe irreparable damage to the hydraulic power steering pump.

This is more of a simplified explanation which has been provided; a hydraulic power steering pump is much more complicated. There are a lot of complicated physics involved and several internal moving parts (e.g. rotors vanes etc…) inside a power steering pump. However, this simplified overview should be enough to give you an idea about the inner workings of a hydraulic power steering pump and why it is important to keep the hydraulic fluid topped up and to the correct level.

5 Common Causes of Power Steering Pump Failure

- Low Power Steering Fluid: as previously explained, hydraulic fluid lubricates the steering pump as it is compressed. Low levels of steering hydraulic fluid are harmful to the steering pump as its moving parts will be in contact metal-to-metal. This damages the steering pump’s moving parts. Pumps with low hydraulic fluid levels make a ‘whining’ noise as you turn the steering wheel. If the power steering pump is severely damaged, you will hear ‘shrieking’ noises as soon as you start your engine. Another symptom of low power steering fluid is finding your vehicle hard to steer. Top up your vehicle’s power steering reservoir and turn the steering wheel left and right for approx. 20 turns. If the sound does not stop it is very likely that your hydraulic power steering pump has suffered irreparable damage and will need complete replacement.

- Worn Out Power Steering Pump seals: a power steering pump may leak due to worn-out seals, natural wear and tear, or premature wear caused by contaminated steering fluid. It is important to address this issue immediately to avoid more damage to your power steering system.

- Cracked Power Steering Pump Case: As power steering pumps handle a lot of pressure, its case may crack over time and thus leak hydraulic fluid. The case construction varies from manufacturer to manufacturer. Some cases are more prone to crack than others.

- Bad Power Steering Pump Bearing: The power steering shaft bearing can get damaged due to several reasons: normal wear and tear, vibrations and excessive force caused by a defective serpentine belt or tensor. Bad power steering pump shaft bearings may grind, whine, or squeal. They can also stick, preventing the power steering pulley’s rotation, which may harm other accessories driven by the serpentine belt like the alternator and the air conditioner compressor. If you hear one of these noises and your power steering fluid reservoir is full or the sound does not disappear after you top it, your pump bearing might be worn out.

- Bad Power Steering Pump Control Valve: This valve can get stuck which causes a loss or an excess of pressure within the pump. Lack of hydraulic fluid pressure will cause hard steering when turning, while excessive pressure can cause the power steering pump to overheat and damage the pump’s seals and power steering hoses.

Brand-new Power Steering Pump VS remanufactured

Power steering pumps have many internal moving parts such as seals, bearings, joint caps, shaft, rotor, springs etc… that need to be perfectly installed for the steering pump to run properly and trouble-free.

Remanufactured or refurbished power steering pumps are a tempting choice over brand new power steering pumps because they are cheaper than the OE parts. However, no matter how thorough remanufacturing processes are, there are plenty of chances for human error. A Brand new Aftermarket Power Steering Pump does however compete with remanufactured when it comes to pricing.

A remanufactured power steering pump may not fail catastrophically but it can be out of specs which may lead to damage to other related expensive power steering components.

Remanufactured power steering pumps are usually not subjected to the same extensive quality controls when you compare it to a brand-new high-quality power steering pump. A remanufactured power steering pump is also likely to have a warranty. However, this does not usually cover the labour cost to repair the potential damage caused to other related parts of your hydraulic power steering system or the labour of re-doing the pump replacement if it were to fail.

About BGA (BG Automotive):

BGA is an Automotive Aftermarket parts supplier, celebrating over 90 years of OE manufacturing heritage as the aftermarket division of the largest privately owned OE supplier, 4BG Group, established in 1929.

BGA focuses on providing one of the largest ranges of high quality, competitively priced parts in the aftermarket containing Auxiliary Drive, Camtrain, Cooling, Gaskets, Lubrication, Power Steering, Steering & Suspension, Timing Belt Kits, Timing Chain Kits and Transmission.