Modern internal combustion engines have two ways of synchronizing the crankshaft and the valvetrain to ensure a proper combustion cycle. Some engines are belt-driven which means that this type of engine is synchronised by a timing belt – usually made of rubber. Other types of engines are synchronised by a chain – usually made of metal. These belts/chains act as a synchronisation link between the crankshaft and the camshaft in a combustion cycle.

Although both types of engine working principles are the same, we are going to be focusing on chain-driven engines for the purposes of this article. The timing chain, tensioner, and other components like the guide rails must be kept in perfect shape and working conditions to ensure a proper combustion cycle and to avoid serious engine damage.

Crucial steps to follow when fitting a Timing Chain

The timing chain must be perfectly mounted to ensure proper synchronisation between the pistons and the valves to avoid a collision between the two in a combustion cycle. Crucial steps must be followed and adhered to ensure a good result and to avoid a catastrophic failure of your engine.

Installing a timing chain is a precision focused job which is likely to require specialised tools which should be ideally performed by a skilled mechanic/competent DIYer.

- Have a workshop manual handy to check the routing of the timing chain, torque specs of the bolts, screws, tensors, and other vital components. This can also act as a guide which can be followed to ensure that the correct process is being followed throughout installation.

- Check for marks on the crankshaft and the camshaft sprockets. The new timing chain marks or bright links must match the crankshaft and camshaft sprockets to ensure that the engine is correctly synchronised to avoid piston & valve overlap/collision during combustion. Following the manufacturers marks ensure that the engine is properly timed (intake and exhaust valves will be synchronized with the crankshaft) which results in a perfectly tuned up engine.

- Before installing the new timing chain – make sure that your engine is set to its top dead centre. The safest way to do this is using a timing kit. You need to use the right timing kit for the engine you are working on. The timing chain kit locks the crankshaft and the camshaft in position to ensure that the engine is in the top dead centre. If you don’t have access to the timing chain kit, please check the vehicle’s workshop manual to see if this procedure can be done by hand.

- Ensure that the gears are properly lubricated ideally using engine assembly lube before installing a new timing chain.

- Most timing chain tensioners are automatic, so you don’t have to adjust the chains tension manually. If you are working on an engine with a standard tensioner, make sure to tighten the chain following the workshop manual’s instructions. It’s important to have the chain perfectly adjusted (not too loose or too tight).

- Before installing the timing chain cover, double-check that the sprockets are properly aligned with the chain and that everything is perfectly lined up.

Timing Chain Kit VS individual components

Timing chains and tensioners are subjected to more stress than any other timing components because they endure sudden accelerations and decelerations, speed changes and wear.

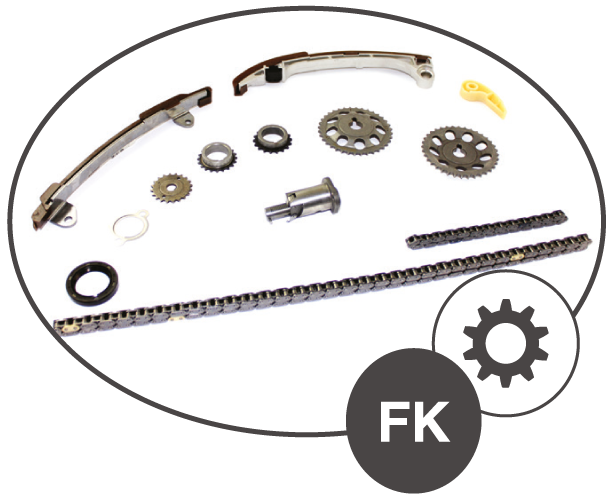

Replacing a timing chain is an expensive and time-consuming job. It is best to replace as many parts as possible to ensure that the engine will be as good as new and thus prevent unnecessary repairs down the line. Spare parts manufacturers are aware of the items that wear out the most in a specific engine type/model and thus most manufacturers of kits supply all of the necessary parts to perform a complete job. Buying a full timing chain kit instead of just individual components will save you a lot of money and will prolong the life of your engine.

BGA Boast the most ‘Complete’ Kits in the aftermarket eliminating time and hassle when it comes to replacing a worn chain. See the below offerings.

Most common reasons for timing chain failure

Timing chains are subjected to a great deal of stress due to the functions it performs. It is recommended by most manufacturers to replace the timing chain between 80,000 – 120,000 miles.

Always replace the timing chain and its accessories in accordance to the vehicle’s user maintenance manual schedule. Being aware of strange noises and associated symptoms of a bad timing chain/tensioner when the vehicle is in the mileage range for replacement would be beneficial to avoid a total catastrophic failure of your engine. Replacing them in due time will prevent the valves and pistons from colliding if the chain or tensioner were to fail. The timing chain/tensioners can fail because of wear and tear, engine seizure, overheating or stress caused by excessive or poor oil pressure.

About BGA (BG Automotive):

BGA is an Automotive Aftermarket parts supplier, celebrating over 90 years of OE manufacturing heritage as the aftermarket division of the largest privately owned OE supplier, 4BG Group, established in 1929.

BGA focuses on providing one of the largest ranges of high quality, competitively priced parts in the aftermarket containing Auxiliary Drive, Camtrain, Cooling, Gaskets, Lubrication, Power Steering, Steering & Suspension, Timing Belt Kits, Timing Chain Kits and Transmission.