A drive belt is a continuous belt driven by the engines crankshaft which makes the engine’s accessories such as the power steering pump, alternator and AC compressor work. Depending on its design, an engine can have one or more drive belts.

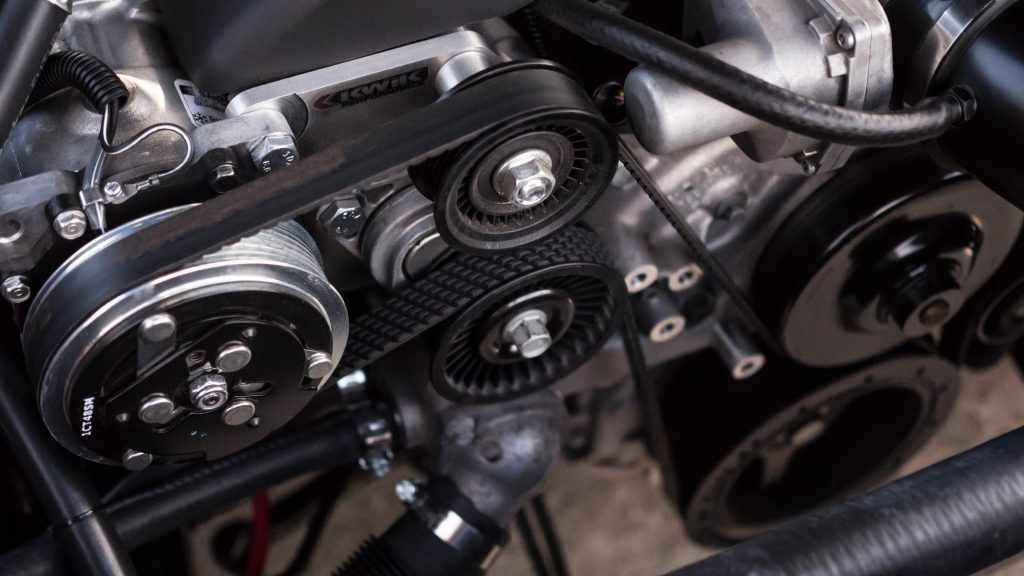

Drive belts are also known as serpentine belts because they wind over pulleys and any other accessories. Another name for a drive belt is a multi-v or poly-v belt due to its V-shaped grooves. Drive belts are often guided and tensioned by idler pulleys and belt tensioners. Belt tensioners and idler pulleys keep the belt in place preventing it from slipping by keeping a slight tension on the belt.

Modern engines have one or two drive belts, and almost all modern tensioners are spring-loaded or use a similar system to keep the belt/s properly tensioned. Old engines used multiple drive belts to power all the accessories which required more space and made the engines harder to maintain.

Symptoms of drive belt failure

- Strange Noises: There are several reasons why drive belts may make screeching, whining or squealing noises. The noise may be heard as soon as you start the engine, when turning the steering wheel or simply when you turn on the AC. As you turn more accessories on this will put a bigger load on the drive belt. These noises can be caused by a loose or misaligned drive belt or engine coolant / oil / debris / water / etc. contamination on the belt making it slip.

As driving belts wear out, they harden and lose grip which makes it more susceptible to be slippery and noisy. Tensioners, pulleys, or bearings (e.g. steering pump bearing) can also make similar kind of noises when they fail which in turn will damage the drive belt in the process. - The first step to check if the driving belt may be the culprit and needs to be replaced is to remove it and start the engine for a short amount of time. If the engine’s water pump is driven by the timing belt, you should not leave the engine on for more than 5 minutes or so – you don’t want the engine to overheat.

Listen carefully as the engine is running without the drive belt. If you don’t hear any strange noises, turn the engine off and try to manually rotate the tensioner/s’ pulleys, idle rollers, and the pulleys of each of the accessories to check if they are hard to turn. Then check for signs of wear on the driving belt. If your driving belt is ok and you can’t detect any other problems on the tensioner, pulleys, and rollers, reinstall the drive belt, turn the engine on and use a stethoscope or a long screwdriver to check for noisy components individually. - Cracks and Wear Signs on the Belt: With time, friction and temperature changes, etc… drive belts will wear out. Signs of wear on the drive belt are cracks, chunks missing, degradation, abrasion marks (the belt’s backside looks glazed or shiny, and in some cases, the fabric and cord get exposed), uneven rib wear, visible pinholes on the belt’s backside, visible damage to the outermost ribs and the belts surface becoming wet or sticky. Depending on the vehicle these faults can be seen with the belt in place. However, it may be required to completely remove the belt for a full inspection depending on the space within the engine bay.

- Heavy Steering: Vehicles with hydraulic power steering usually has the power steering pump driven by the drive belt A slipping drive belt will fail to provide the power steering pump enough force to work properly, making your vehicle harder to steer. A snapped drive belt will cause your power steering pump to stop working and your steering wheel to get heavy and hard to turn.

- Alternator Problems: A loose drive belt will also fail to provide enough rotational speed to the alternator reducing its ability to generate enough power to charge the battery. This may cause the battery light on the vehicle’s instrument cluster to flash as a warning that something is wrong with the alternator / charging system. When a drive belt snaps the battery light on the instrument cluster will stay on as the alternator will stop working – the engine will stay on until the battery does not have enough charge to keep it running.

- AC Problems: A similar problem may happen with the AC compressor. A loose or stretched drive belt can cause the AC compressor to work inefficiently and completely stop working if the drive belt snaps.

- Engine Overheating: Vehicles in which the drive belt propels the water pump will overheat if the belt snaps as the water pump will stop working. You may have noticed other associated symptoms and should have stopped the engine before it has started to overheat.

When should a drive belt be changed?

Drive belts power many accessories on a vehicle; some accessories are more important compared to others, but it is important to know that a snapped drive belt can leave a vehicle stranded on the side of the road as none of the accessories running of the belt will function. A snapped driving belt can also damage other components of the engine. As the driving belt snaps, vehicles with hydraulic power steering will immediately become hard to steer which is dangerous as it might lead to a crash.

As some vehicles run the coolant pump off the driving belt, if it were to snap the vehicle will overheat, leading to severe engine failure such as a blown head gasket or cylinder wrapping.

A good practice and a reasonable preventive maintenance item should include replacing the drive belt following the vehicle’s manufacturer schedule. Drive belts are usually changed between 60,000 and 100,000 miles (around 95,000 and 160,000 km) and should be inspected yearly. For timing belt-driven vehicles, it is advisable to replace the accessory drive belt every time the timing belt is replaced.

If your timing belt is causing noises, it’s always best to replace it as soon as possible.

The drive belt should also be changed as soon as you notice any visible signs of damage like cracks, degradation signs, and/or if you find any trace of coolant, engine oil, or water over the drive belt’s surface. Oil and coolant contamination degrade rubber compounds, weakening them and making the drive belt prone to slippage which will eventually fail.

Misaligned or worn-out pulleys can damage the timing belts surface. Always check the drive belt for damage after replacing a worn-out pulley or a drive belt tensioner. If you suspect that the drive belt has suffered any damage, it is recommended for it to be replaced to avoid any future problems.

About BGA (BG Automotive):

BGA is an Automotive Aftermarket parts supplier, celebrating over 90 years of OE manufacturing heritage as the aftermarket division of the largest privately owned OE supplier, 4BG Group, established in 1929.

BGA focuses on providing one of the largest ranges of high quality, competitively priced parts in the aftermarket containing Auxiliary Drive, Camtrain, Cooling, Gaskets, Lubrication, Power Steering, Steering & Suspension, Timing Belt Kits, Timing Chain Kits and Transmission.