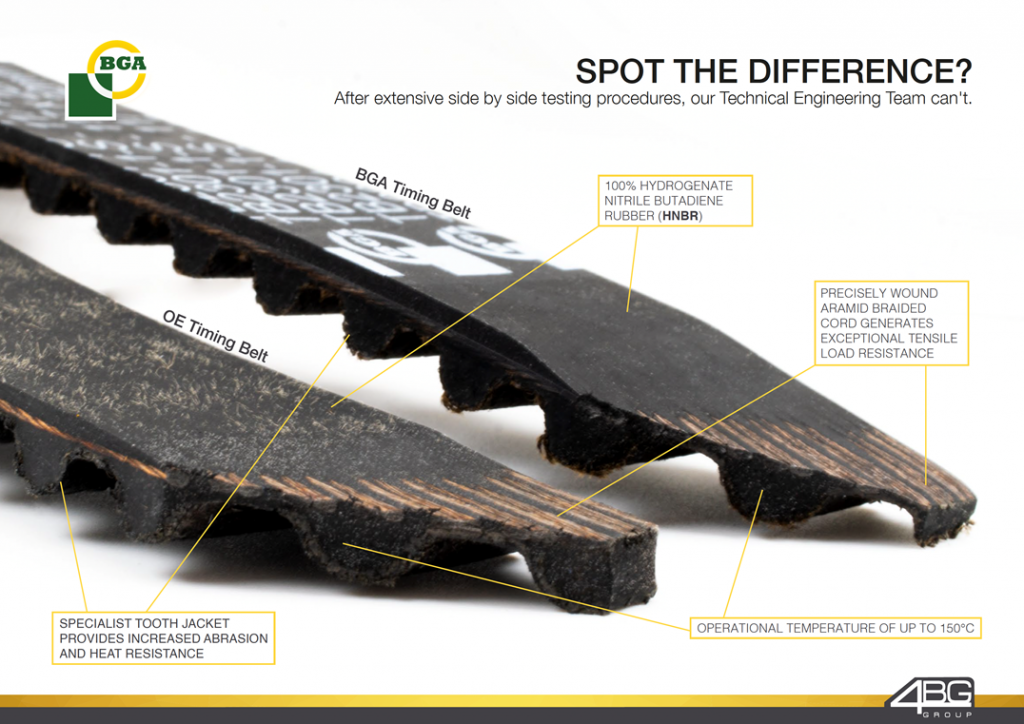

Can you spot the difference between OE and BGA Timing Belts?

With extensive side by side real life simulation on bespoke machinery in BGA’s Research & Development Center, we can’t either.

After an in-depth material analysis with a specific OE brand, BGA belts and the OE belt both contained 100% Hydrogenate Nitrile Butadiene Rubber (HNBR), Precisely wound aramid braided cord generating exceptional tensile load resistance, and specialist tooth jacket providing increased abrasion and heat resistance.

All belts from BGA’s production line are thoroughly tested for 41 days/984 hours on bespoke testing and measuring machines simulating a real-life driving experience equating to 63,960 miles. Upon cycle finish, both OE and BGA belts were analysed and measured to have equal degradation.

Important Note regarding Timing Belts:

Timing belt replacement intervals quoted by the manufacturer should be regarded as the maximum. Due to variations in vehicle usage and operating conditions the belt may need to be replaced earlier than specified.

If there are any doubts as to the serviceability of the belt and its associated components, they should be replaced.

It is important that you consider the items above and discuss them with your customer.

Timing belts degrade over time and start drying and cracking as they are exposed to external elements. However, if they are replaced at the intervals fixed by the manufacturers, it’s hard for a timing belt to fail prematurely.

About BGA (BG Automotive):

BGA is an Automotive Aftermarket parts supplier, celebrating over 90 years of OE manufacturing heritage as the aftermarket division of the largest privately owned OE supplier, 4BG Group, established in 1929.

BGA focuses on providing one of the largest ranges of high quality, competitively priced parts in the aftermarket containing Auxiliary Drive, Camtrain, Cooling, Gaskets, Lubrication, Power Steering, Steering & Suspension, Timing Belt Kits, Timing Chain Kits and Transmission.